We control information

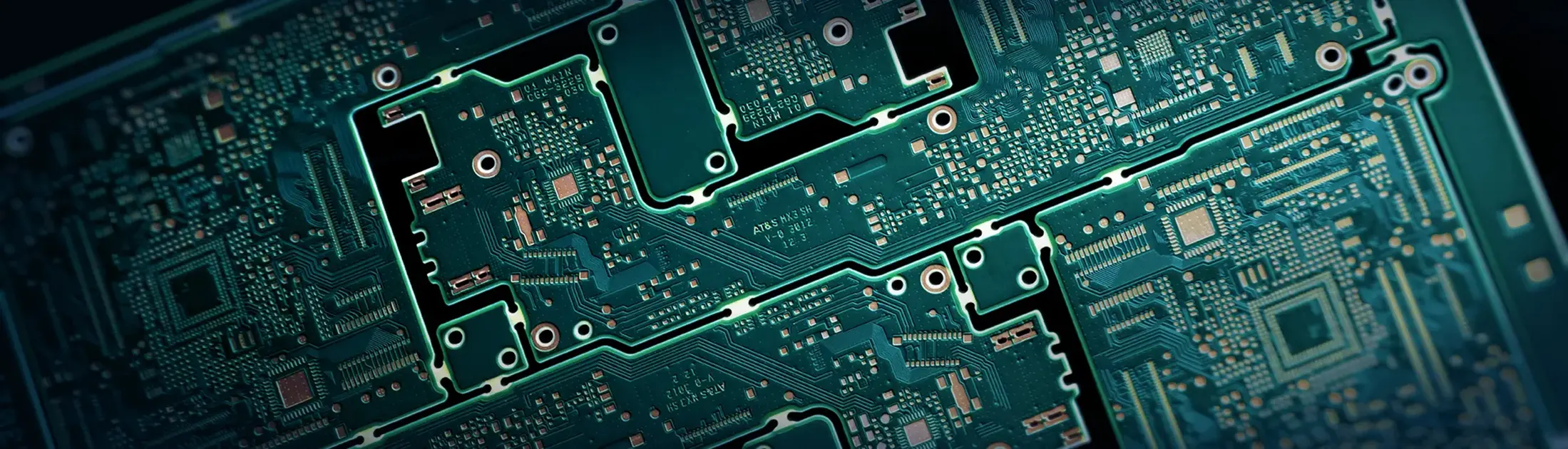

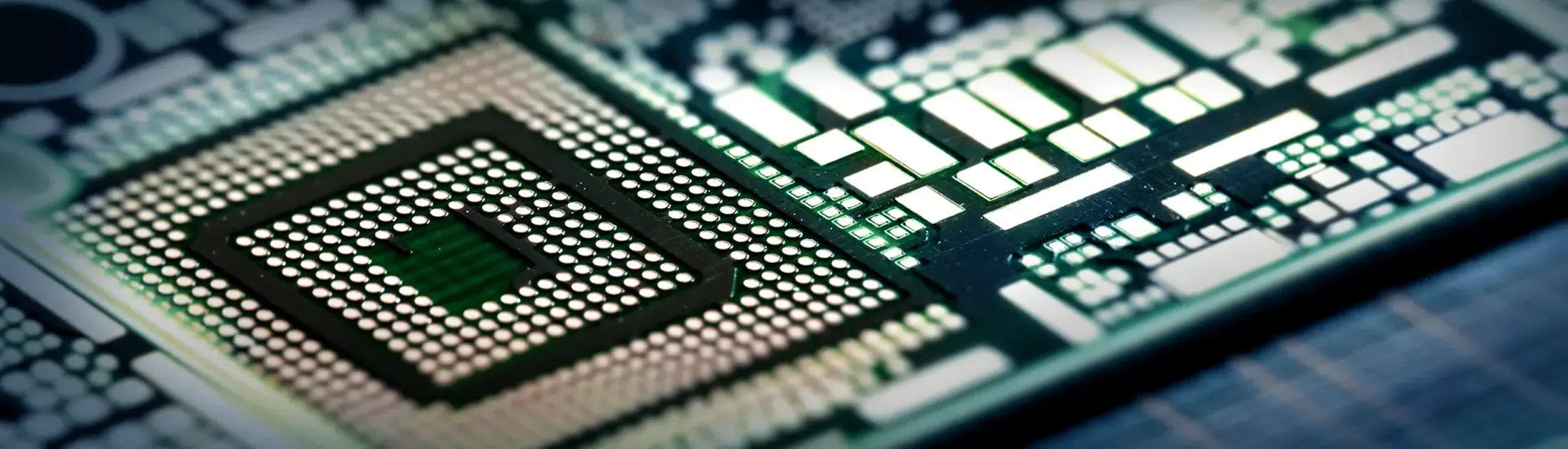

As leaders in the sector when it comes to technology, our printed circuit boards and substrates guarantee maximum possible performance within the smallest space. Our circuits can be adapted to any profile of requirements with our advanced technologies, whether as a mainboard for PCs, smartphones and servers, or as control systems for cars or industrial plants.

Our product range includes, on the one hand, high-precision IC substrates, which play an indispensable role for supercomputers, and, on the other hand, printed circuit boards of the highest quality, which can be found, for example, in power electronics for the future-forward electric car infrastructure.